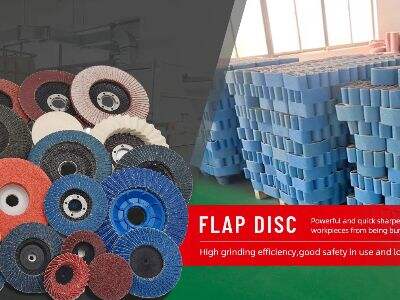

Flap discs are a highly popular tool in the sanding and grinding industry. They’re all different, and they all do different things. The two most common flap disc forms are T29 and T27. But what separates these two, exactly? What is the difference between T29 vs T27 flap discs We will take an in depth look at the shape of the flap disc to help you decide which one you need for your grinder.

Distinguishing T29 vs T27 Flap Disc Shapes

And what is the difference between T29 and T27 flap disc? T29 The T29 flap disc gradually remove the flap from the flap disc, which is the transformation of non-woven wheels. In contrast, a T27 flap disc is much more flat-shaped with the flaps placed in a straight way.

T29 vs. T27 Flap Discs

If you need to make a decision between T29 or T27 flap discs, don’t hesitate to decide the work. T29 flap discs are more aggressive which makes it perfect for grinding and blending at a smaller angle. The conical shape simplifies sweeping cutting spring, so it is suitable for quick removal of material.

T27 Flap Disc This design is used for grinding applications, such as flat grinding. The fact flat shape offers a larger surface contact with the work to a greater finish. The T27 flap disc is ideal for light deburring, finishing and flash removal.

T29 or T27?

So which T29 or T27 flap disc shape is best for you? The response really depends on the task you are setting out to tackle. If you need to remove a lot of material fast, you can’t beat the T29 flap disc. The cone shape is designed for quick stock removal to speed-up the rough grinding process.

But for a polished finish on a flat surface, don’t bet against a T27 flap disc. A flat shape allows for fine control, enabling you to produce a polished finish on flat surfaces.

The Effects of Flap Disc Shape on Performance

The shape of the flap discs is important to their working performance. It's the angle and layout of these flaps that direct how the disc engages the workpiece. The T29 flap disc structure shape is more aggressive and more durable as to the T27 which is flat. By contrast, a T27 flap disc is designed to achieve better surface contact and a finer finish with a relatively flat shape.

In summary, 6 disc sandpaper knowing the differences between T29 and T27 flap discs is critical for selecting the right tool for the application. When you want to strip something down or achieve a final finish, a flap disc shape can help you do the job right. So the next your project demands some sanding or grinding, think about the shape of that flap disc and how it can meet your needs. Because Pangea has the supplies you need in order to do it right!

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

AF

AF

LA

LA