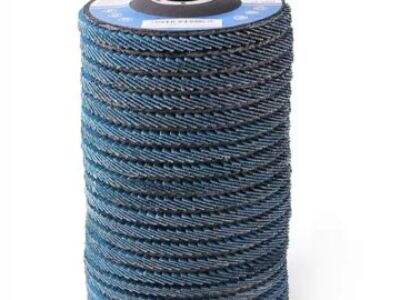

Flap discs are useful for sanding and smoothing a variety of materials. However, the question of how long a flap disk can last never popped in our minds. So, let’s take a look at how long do flap discs last, and give you some hints and tips on how to make them last longer.

What factors determine their durability?

Flap disc life can vary depending on a few consideration. The first thing we will mention will be the issues regarding the material of the flap disc! The Best Materials We have tested hundreds of different abrasives to find the one that works the best with Flapster! Our Flapster flap discs are made with longevity in mind! The way flap discs are used can be yet another factor which influences their longevity. The lifetime of your flap disc also depends on its use; if you are using it for heavy duty sanding or grinding tasks, it will not last as long as a flap disc you use for light work.

Pro tips to extend the life and ensure the best performance out of your flap discs.

Bringing them to last for as long as possible, however, can be done using flap discs properly. One piece of advice is to ensure that you are using the correct flap disc for the job. Flap Disks One common issue is that the flap disks are too aggressive for the material you are sanding. Another suggestion is to clean the flap discs on a regular basis to remove any accumulated dirt or materials that will reduce their efficiency. In addition, keeping your flap discs in a dry area free from humidity will also help elongate their lifespan.

When to replace it.

There are a couple of things to look out for that say its time to swap out your flap disc. When you see that the granulate on the flap disc has become flat or uneven it is probably time for a new flap disc. Another indication is when the flap disc is not cutting or sanding as well as before. If sparks or smoke start to occur while using the flap disc, that is also a sign it needs to be replaced.

Can you rejuvenate, refurbish or recondition flap discs?

Do flap discs have a possibility of being reconditioned or refurbished for further use. It is often possible to clean the dish discs to de-glaze them and extend their life, but after the dish material is worn out it can be difficult to repair. With worn fiber and concrete discs it is most economically compatible to replaces them machine replacement.

Comparison of Flap Discs for Longevity and Cost per Unit Had a bit of a curiosity about these and decided to investigate a little further.

Different kinds of flap discs are available to wait you choose long lasting and inexpensive! Heavy Duty Some flap discs are designed for use on heavy duty applications and other of high-production. Although these flap discs may cost a bit more to begin with, they provide better value in the long run because they will last you longer. However, there are also some affordable flap discs that will likely wear out faster. When selecting a flap disc you are trying to consider the best option for your brush, and your budget.

Finally 6 disc sandpaper as you can see flap discs are very productive for sanding and polishing materials, however its longevity will depend on many factors. You’ll get the best value out of your flap discs by embracing the pro tips and observing the signs that let you know when to replace your flap disc. If your flap disc isn’t reworkable or available for reconditioning, comparing the wear of different kinds of flap discs can help you determine which one is best for longer life and the most for your money. Just always remember to maintain your flap discs and it will stay longer and applicable for the job.

Table of Contents

- What factors determine their durability?

- Pro tips to extend the life and ensure the best performance out of your flap discs.

- When to replace it.

- Can you rejuvenate, refurbish or recondition flap discs?

- Comparison of Flap Discs for Longevity and Cost per Unit Had a bit of a curiosity about these and decided to investigate a little further.

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

AF

AF

LA

LA