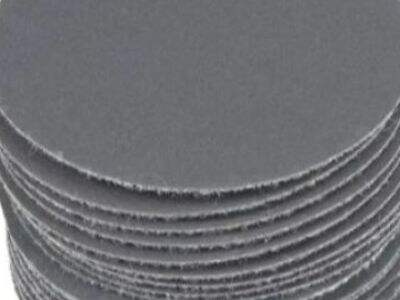

Flap discs are one of the tools that we value most in our workshop. And so, as to help them to last them a long time, we have to keep and take care of them correctly. Here are a few tips that may help you store and retain flap discs for a longer lifespan.

Store flap discs in a cool, dry environment. This will prevent moisture and humidity from damaging something. Flap discs, themselves, don’t like to get wet, so store them in a dry place. Store flap discs in a cool and dry place as moisture can affect them, but the cooler they stay, the longer they stay in good shape.

Keep flap discs away from oil and grease when not in use. These can cause the flap discs to not function properly. Clean abrasive tools work their best, and flap discs are no exception. They are only fairly immune to dirt so you must keep them away from oil, grease, or other dirty things. This allows the flap discs to be more effective and have a longer lifespan.

Store flap discs in their protective cases. This will shield them from grime and dust. When not used, flap discs tend to get contaminated easily. Protective cases are a good way to keep them clean. So guide them towards us to avoid any damage, and keep them in shape too.

Sanding Disc after every use. That means getting out metal shavings and other dirt. There are many types of abrasives and after using flap discs, they would require thorough cleaning to eliminate any accumulated dirt. Cleaning flap discs is what you need to do to make them work better and last longer, thus further using them.

Inspect your flap discs for a worn state. Check them for fraying or discoloration and replace them if necessary. Disc flaps can get exhausted after some time, particularly if we utilize them a great deal. Be sure to inspect them frequently for signs of damage. If we observe any problems with them, we must substitute them with new ones. This will ensure that our flap discs perform well.

If we hope that they will last for a long time, Sand Paper the maintenance of the flap discs is important. These tips can help us to ensure that our flap discs lasts longer and performs better when we need them. So, let’s keep our flap discs in a dry, cool place (preferably made out of virgin woods to prevent excess moisture) away from oil and grease and in their protective cases, clean our flap discs after use to reduced wear and tear. This allows us to keep our flap discs in the workshop and use them when we need to.

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

AF

AF

LA

LA